Hi everyone! My name is Florian Gregor, I am 24 years old and from Salzburg, Austria. I have been studying Forest Products Technology and Timber Constructions at the University of Applied Sciences in Salzburg. In my bachelor degree course we have been working a lot with wood materials. Due to the University I studied at, I am constantly confronted with the topic of sustainability. This year I was in a bachelor project where we had to plan a new Funeral Hall for a neighboring village. During this project we had to research about the funerary culture of different religions. Then we had to choose a topic for our bachelor thesis, which was connected to our project. I was searching for ideas to construct biodegradable and ecological friendly burial containers. From the beginning, it was clear to me that the urn had to be sustainable since it will be buried. In the process of finding a way to make the urn as sustainable as possible, I stumbled upon Ecovative Design and their unique Mushroom Material. From that moment on I knew this was what I was looking for. At first I ordered 3 GIY (Grow it Yourself) bags from Ecovative. As the bags arrived, I started to rehydrate the material with water and flour.

Everyday I checked my GIY bags to see if anything was happening. As I saw the first white mycelium strings I was just completely astonished and I thought, “this project can really work."

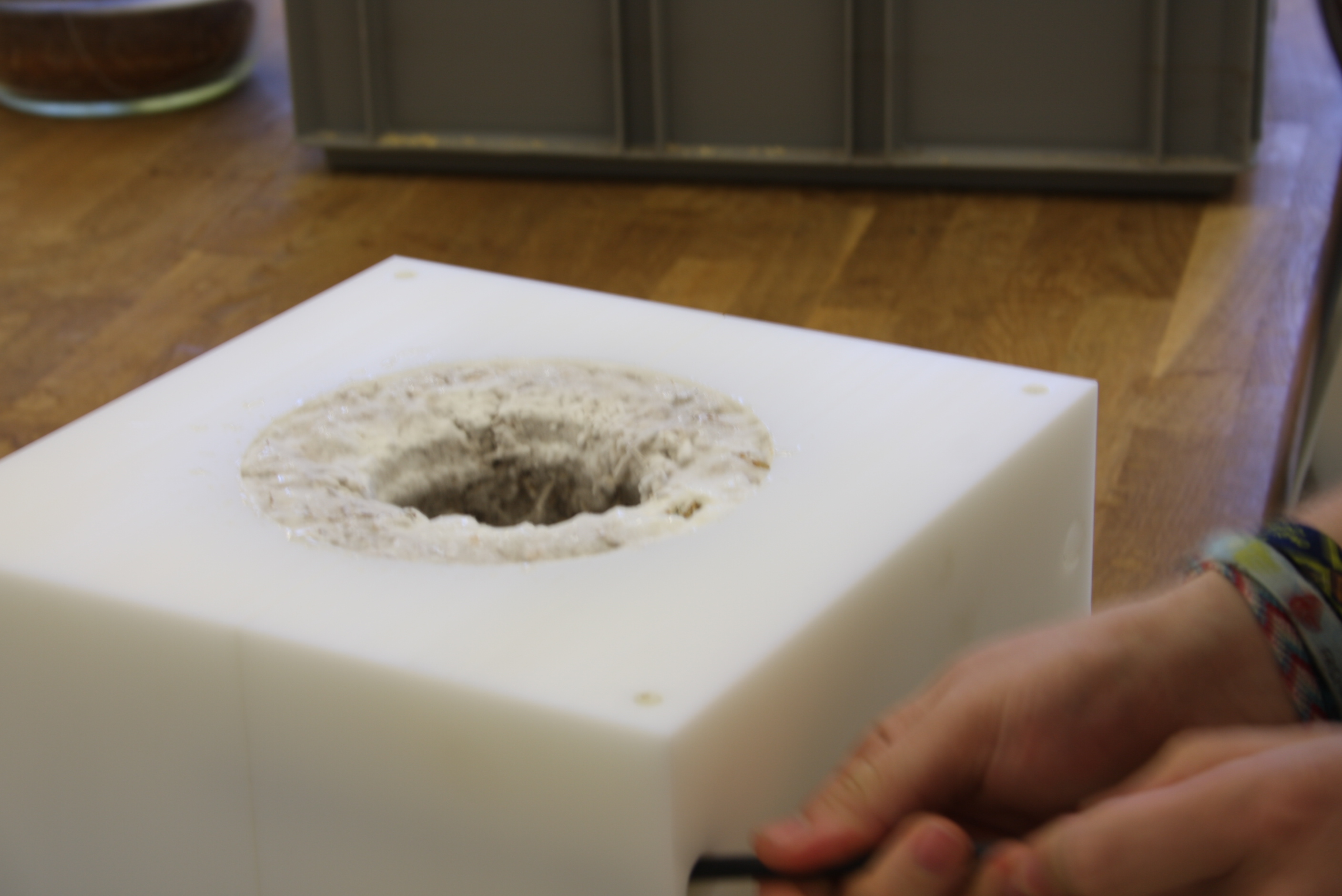

Then I made two negative molds, one for the urn itself and one for its lid in which the Mushroom Material could grow. For the mold I used a thermoplastic material, which I processed using a CNC machine. In each of the two molds I had to drill holes into the top cover to create airflow- this is necessary for the growing process.

After finishing the molds and six days of waiting (this was the time it took the dehydrated material to rehydrate), I had to tear up the white spongy mass to make it fit into my molds. I had to make sure that the molds were sterile, to prevent the growth of any other type of fungus. Because of that, I cleaned everything thoroughly with ethanol. It took another seven days before I was able to take the molds apart.

In that moment I really trembled with excitement, my hands were shaking and I was completely nervous – BUT it worked out so well. Then the time came for the most important and tricky part of the process: I had to weigh the urn in its wet state, calculate and dry the mushroom urn down to 35% of its original weight. At this point the growing process of the mushroom is fully stopped. And here is the first urn prototype made with love:

So, as you can see the Mushroom Material works perfectly for modeling a biodegradable urn. Although there is room for improvement, such as decreasing the porosity of the urns surface, I am convinced that this could be a realistic solution for the rapidly increasing problem of space. It is cheap, biodegradable, ecofriendly and its production is not too complicated. - Florian Gregor, BSc